Reuse your mechanical wear parts

There are huge advantages in reusing various parts in a production facility. It is a benefit for both the environment, as well as company finances.

For a long time, it has been an established method for Alfotech to reuse mechanical wear parts in our customers' facilities. And Cocio is one of our customers who has achieved significant financial advantages from this procedure.

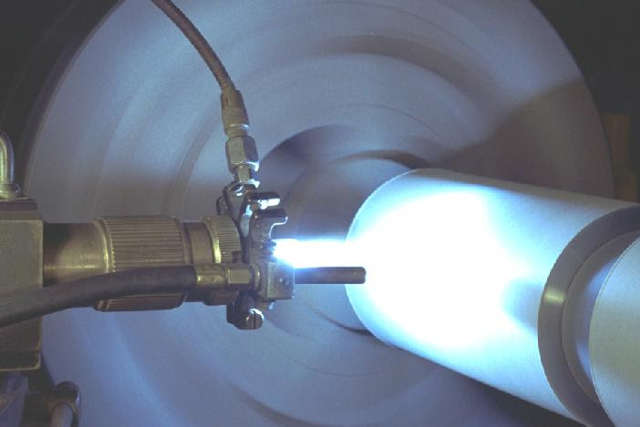

Throughout decades, Alfotech has delivered solutions that - not only allow for reusing expensive components for production - but also extend component life span by up to 8 times the normal life expectancy.

"As of this point we are exchanging gaskets 2-3 times a year and we have had the same pistons for 4 years now. We have had a significant economic advantage with this approach and strongly recommend the hard metal solution," says Bo Boesen, Cocio's Technical Manager

The reusable components include pistons, mechanical seals, valve gaskets, and the likes. These are often quite expensive to purchase and have a limited life span. However, as many of the parts are made reusable it leads to huge savings in production costs.

The advantages of recycling the components are many, among other:

- Maximizing life span

- Reducing potential production halts

- Improved financial situation

- Sustainability and recycling

- Wear and tear that is often transferred to components that are much cheaper

If you have a wear problem, we are happy to give you our assessment

We continuously optimize our solutions aiming to achieve an important gain for our customers - often through the combination of improved utility and reduction of production costs. In this manner, we build a trustworthy partnership with our customers, so we can continue to develop new solutions to their production facilities in the future.

If you have a wear problem that you would like to have assessed, Alfotech is available with both our extensive experience and comprehensive technical knowledge.

da

da

de

de

en

en

sv

sv