Are you faced with the choice between silicone or Teflon hoses but not sure which are best for your needs? Both silicone and Teflon have unique properties that make them ideal for various applications in many industries.

Imagine having complete clarity on which material will optimize your production and improve your bottom line. In this article, we guide you through the important considerations you should make when choosing between silicone and Teflon hoses.

What are silicone hoses?

Silicone hoses are known for their exceptional flexibility and high temperature tolerance. They are made from silicone rubber, a material known for its good resistance to both heat and cold. The silicone is available in a variety of colors, including completely transparent to allow clear viewing of the media.

Silicone tubing is often used in the pharmaceutical, cosmetic and food industries, among others.

Due to the material properties, silicone products can help to significantly improve the production process.

What are Teflon tubes & hoses?

Teflon hoses, also known as PTFE (polytetrafluoroethylene) hoses, are known for their chemical resistance and durability. The material makes them highly resistant to a wide range of chemicals, making them an ideal choice for industries working with aggressive chemicals. Teflon also comes in several different colors, but not in completely transparent.

Teflon tubing can also contribute to reduced energy consumption by taking advantage of the material's energy-saving properties.

Choose the right material

When choosing between silicone and Teflon as a material for your hoses, the first thing to consider is what your specific needs may be. Does the work take place in an industry where high temperature tolerance is necessary, or is it in contact with aggressive chemicals? The choice will also depend on whether flexibility is prioritized over durability, or cost-effectiveness over resilience.

Our Clearway-SD Platinum silicone hose is suitable for use in the food, pharmaceutical and cosmetic industries. It is ideal for process applications that require a small bend radius and high vacuum . The hose is designed for taste and odor-free transport and covers a temperature range from -60°C to +200°C depending on the media.

If your needs place high demands on temperature, pressure and/or chemical exposure, for example with aggressive liquids, we offer Teflon hoses that are well suited for these production environments. It's worth taking a look at our ChemForce ATEX Teflon hose, which is made from corrugated PTFE with a stainless steel braid exterior. The ATEX-approved hose has good antistatic properties, making it suitable for use in explosive environments. It also has excellent chemical resistance and good mechanical properties.

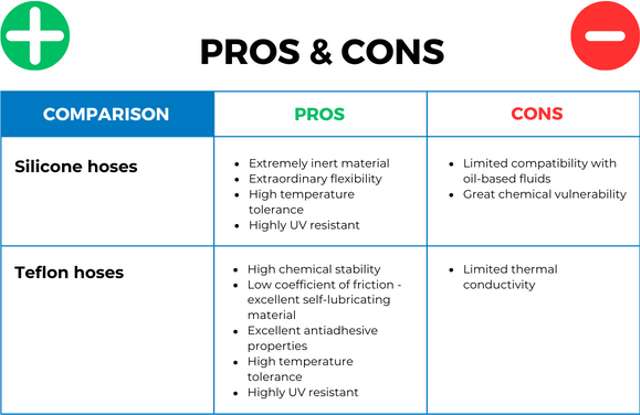

Comparison: Pros and cons

Before making a decision, you should consider the pros and cons of each of the two materials:

Get professional advice from Alfotech

Choosing the right material for your hoses can be a complex process that requires a deep understanding of the different materials and their properties. At Alfotech, our sales professionals are ready to help you make the best choice based on your specific needs.

Contact us by email inquiry@alfotech.eu or phone +45 7020 0422 for professional advice and guidance.

da

da

de

de

en

en

sv

sv