Aseptic couplings, also known as aseptic fittings, are becoming increasingly popular in the process industry, especially in food and pharmaceutical production where sterility and cleanliness are essential. The couplings often provide a safe and hygienic connection between pipes and equipment, minimizing the risk of contamination.

In our new explainer video below, we go through the different types of aseptic couplings, their connections and the relevant standards used in the process industry. We also take a closer look at where in the process industry they are used and show a few informative examples of different types of aseptic fittings.

What types of aseptic couplings exist?

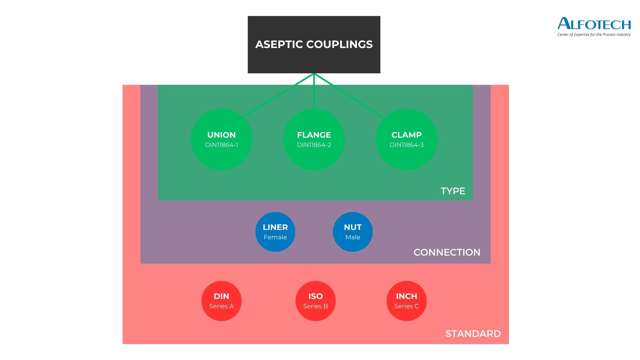

Aseptic couplings come in three main types:

Unions (DIN11864-1)

Often used in smaller applications where flexibility is essential. Known for their quick and easy installation and maintenance. A union comes with a gasket that ensures a hermetic seal, protecting the product from external contamination.

Flanges (DIN11864-2)

Robust and designed for systems that require high stability and resistance to vibration, especially in food production. They ensure a tight connection even under conditions of high pressure or extreme temperatures.

Clamps (DIN11864-3)

Typically used in sanitary applications where quick disassembly is required, for example in pharmaceutical production. Clamps provide flexibility for quick adjustments in the production line and are highly efficient for frequent cleaning and maintenance while maintaining sterility.

What connection types and standards should you know?

Connection types include:

- Liner (female)

- Nut (male)

The liner and nut together form the entire connection between the process hose and the system. An included rubber gasket always ensures a hermetic seal, maintaining the correct flow in the process system.

The aseptic fittings are available for different pipe dimensions and meet a number of international standards, including:

- DIN (Series A)

- ISO (Series B)

- INCH (Series C - also known as DS/SMS couplings)

Where are aseptic fittings used?

Aseptic couplings are widely used in the process industry where sterility and cleanliness are essential for product quality:

Food industry

In the food industry, aseptic couplings are essential for transporting media such as milk, juice and beer sterile through piping systems. They play a key role in pasteurization processes, where it’s necessary to ensure a contamination-free environment to achieve long shelf life and high quality. With the right setup, bacteria, molds and other contaminants can be avoided during production and packaging.

Aseptic couplings are also used to transport fermented milk products like yogurt, where even the slightest contamination can lead to unacceptable changes in taste and texture in a standardized food production.

Pharmaceutical industry

In the pharmaceutical industry, demands for cleanliness are very high. Aseptic couplings are essential for the production of sterile medicines and vaccines, as even the slightest contamination can undermine both the safety and effectiveness of the product. Ensuring hermetic sealing is important in processes such as fermentation, where microorganisms are grown under controlled conditions.

In addition, they’re used for transportation and storage of active pharmaceutical ingredients (APIs) and during filling processes to avoid cross-contamination between different batches. This is especially critical in the manufacture of injectable drugs, where even small amounts of contamination can have serious consequences for patient health.

Biotechnology and the cosmetics industry

In biotechnology, aseptic fittings are often an important part of the process plant. In the production of biological substances such as proteins and enzymes, aseptic systems are used to maintain sterile conditions in bioreactors and during extraction processes.

They’re also used in the cosmetics industry, where they help ensure purity in the production of skincare products and other cosmetic preparations that must meet strict hygiene requirements to avoid skin irritation and other side effects.

Contact us for a solution that fits your production

Do you need advice on choosing the right aseptic couplings for your process plant? Our experts are ready to help you find the best solution for your application. Contact us today on +45 70200422 or send an email to inquiry@alfotech.eu. We offer tailored advice based on your specific needs and ensure you get the maximum benefit from your process plant.

da

da

de

de

en

en

sv

sv