Significant savings

There are several benefits to hard metal coating. Not only does it minimize the risk of costly breakdowns in production, it also extends the lifespan of important wear parts. Overall, you achieve a significantly better operating economy. And this is exactly the case with our customer DANÆG.

Dion Nielsen from DANÆG in Roskilde says:

"It pays off in the long run. We experience significant savings because our wear parts last longer. We don't have to service our machines as often and therefore have fewer production stops. In other words: It's a significant financial gain."

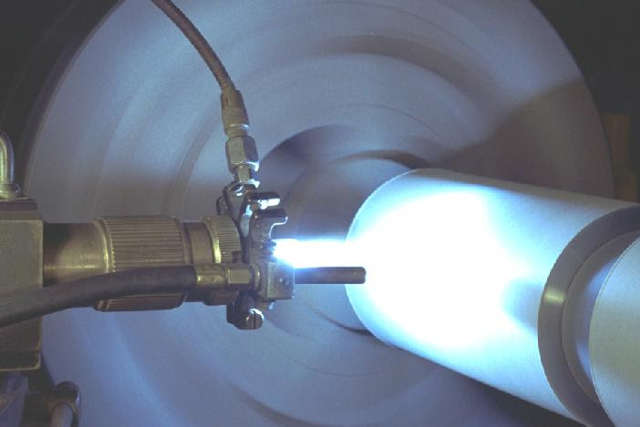

The company has had many of their wear parts coated by us for several years and has been very satisfied with the result every time. At Alfotech, we work with one of the leading specialists in carbide coating. The company is ISO 9001 certified.

What can be hard metal coated?

Almost everything.

From new to used wear parts such as axles, axle bushings, seats and rotating parts as well as pistons and fittings.

Depending on the function of the components, Chromium Oxide, Chromium Carbide, Aluminum Oxide, Tungsten Carbide, Nigrafit and several others are used as coatings. If the wear part is in direct contact with food, FDA-approved materials are used.

About DANÆG

About Alfotech

DANÆG can be traced back to the beginning of 1895. Back then, the company was called Dansk Andels Ægeksport and was founded to take care of the growing export of Danish eggs to England. DANÆG took its current form in 2004 through a merger with Swedish Kronägg.

Today, DANÆG employs around 300 people and has an annual turnover of DKK 900 million.

The DANÆG Group's goal is to launch at least one new, innovative egg product on the market every single year. Every day, 750,000 eggs are hatched. This results in many different quality products. The development activities are coordinated in the product development department at DANÆG in Roskilde.

Alfotech is a Danish-owned company founded in 1984. We represent several international suppliers of quality products and solutions that naturally meet the strict requirements of the industry.

Our customers are from the food, pharmaceutical and chemical industries in Northern Europe. We import, develop and manufacture many of the components used in our solutions. The knowledge we have gained through 35 years of product development gives us great expertise in finding the right solution for your business.

da

da

de

de

en

en

sv

sv