Do you know the differences between CIP and SIP cleaning?

In the food industry, cleaning process equipment is essential, not only to ensure compliance with the most common hygiene standards but also to produce the highest quality food most efficiently.

At Alfotech, we regularly get questions from customers about CIP and SIP. Therefore, this time we focus on the cleaning methods, their differences, and the products we often recommend depending on the production conditions and cleaning method.

Read along and become a master of the topic!

Why process plant cleaning is so important

Thorough and proper cleaning of the processing plant is the foundation for efficient and safe food production, minimizing the risk of contamination and, in the worst-case scenario, injury, while complying with industry food safety standards, such as those set by the EU and the FDA (Food and Drug Administration).

At a time when consumer awareness of food safety is at an all-time high, companies' commitment to clean production processes can directly impact their reputation and therefore their competitiveness in the market.

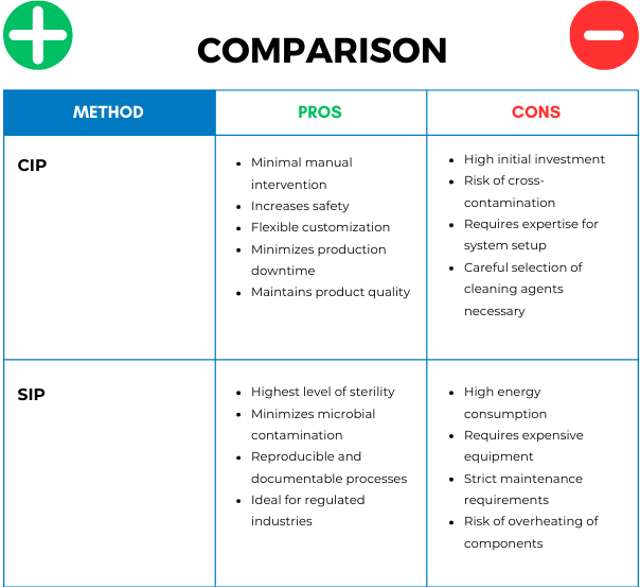

Simple overview: CIP vs. SIP cleaning

CIP (Clean-in-Place) and SIP (Sterilize-in-Place) are the two most common methods in the process industry for cleaning and sterilizing equipment without disassembly.

CIP cleaning, which is often a fully automated process, includes, for example, caustic solution or lye that is circulated through machines and pipelines to remove product residues and microbial deposits. The process ensures an in-depth and effective cleaning without the need for manual labor.

SIP cleaning involves the use of steam or other sterilizing agents to achieve a sterile environment inside the equipment. The method is crucial in productions where sterility is essential, such as in the pharmaceutical and biotechnology industries.

The right hose is essential

Choosing the right equipment for CIP and SIP cleaning is critical to achieving the desired cleaning results. This includes everything from the design of the systems to the choice of hoses and accessories that can handle the specific detergents and temperatures.

CIP cleaning:

The choice of hose for the cleaning process depends on the context in which it is used. For lower concentrations of mixed liquids, we recommend Alichem/SPL, which is constructed from EPDM rubber and has a built-in steel spiral. If, on the other hand, concentrated acid in high solution is used, the Teflon hose FoodForce C is much better suited, as Teflon as a material is much more chemically resistant than EPDM rubber.

SIP cleaning:

Effective steam sterilization requires a hose that can withstand high temperatures and pressure. Our Food Steam food-grade steam hose is a great choice as long as you are not dealing with confined steam. The latter requires the hose to be reinforced, and here Soffione or FoodForce C are ideal candidates.

Ask us if you are unsure

At Alfotech, we are more than just equipment suppliers; we are your partners in production hygiene. Our team of experts are ready to guide and advise you on the best solution for your specific needs, whether it is CIP or SIP cleaning.

Contact us by email at inquiry@alfotech.eu or by phone +45 7020 0422 for a no-obligation chat about how we can help you optimize your cleaning processes and ensure your production runs smoothly.

da

da

de

de

en

en

sv

sv