Today, quick couplings are used in the process industry for working with either compressed air or liquids. They are suitable e.g. for connecting water hoses to fixed installations. Connections can thus be changed quickly and easily, hence their name. As with so much other technical equipment, this product category has also undergone significant quality developments, which have had a major impact on how they are used today in various production plants.

Read our mini guide below to find out more about quick couplings.

Construction and advantages of the quick coupling

Historically, quick couplings have been manufactured in either nickel-plated steel or brass, and for many years, KS quick couplings in these materials were widely used in Denmark for work with compressed air. However, they were later phased out and Nito couplings in the same materials quickly took over the market. These types of couplings are still cheap to buy today, but unfortunately, they are worn out relatively quickly by the environment in the process industry. This increases energy loss and thus operating costs.

Stainless steel couplings, including Nito-compatible models first introduced to the Danish market by Alfotech, are considerably more durable and better suited for fluid production environments. They are widely used in the process industry today and are characterized by the built-in balls which ensure resistance to pressure.

The 3 main advantages of stainless-steel quick couplings:

- Good resistance to temperature and pressure (up to 90°C and max 25 bar)

- Longer service life ensures greater reliability and better operating economy

- Compatible with other common Nito products

Types and applications

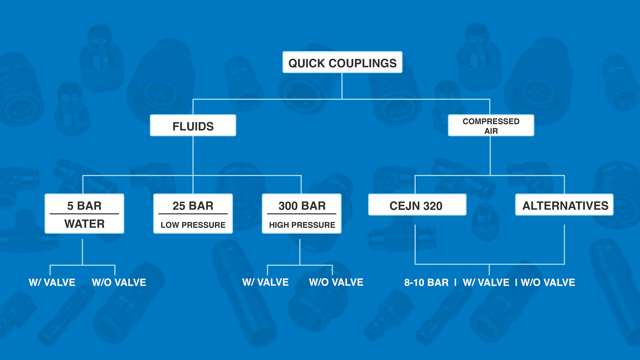

Quick couplings are used for industrial hoses for both liquids and compressed air. In both categories, it is the working pressure that determines the typical applications.

When working with liquids, a working pressure of either max 5 bar (water), max 25 bar (low pressure) or max 300 bar (high pressure) is typically required. When working with 25 bar it is often in connection with low pressure cleaning systems that Alfotech's low-pressure coupling housing with fully vulcanised protection in food grade rubber is used. If you work with chemical fluids instead and want to avoid reactions with other fluids, we recommend drip-free Cejn couplings, which ensure zero spillage and eliminate contamination and air ingress when coupling or decoupling.

When working with compressed air, a distinction is made between Cejn 320, which is a common European standard, and other alternatives. Most components in this product category such as coupling housings, coupling nipples, and hose tails are Cejn 320 compatible. Often the working pressure is 8-10 bar, although most quick couplings for compressed air are approved for max. 20 bar.

We'll help you find the right quick coupling

Do you need advice and guidance on the use of quick couplings in your production? If you still have questions despite our mini guide above, don't hesitate to contact us. We are familiar with various operational scenarios and have decades of experience in this particular product category. Our sales consultants are ready for a chat - call us on +45 7020 0422 or send an e-mail via inquiry@alfotech.eu. Then we'll help you find the best quick coupling for your needs.

da

da

de

de

en

en

sv

sv