Are you looking for a temperature-resistant hose for your process plant?

From extreme heat to sub-zero temperatures, no matter how a hose is used, the temperature conditions in production affect its performance and lifespan. That's why it's important to choose the right one for the job.

In this edition of the Hose Selection Guide, we take a closer look at how heat and cold affect a hose. Plus, we'll give you some tips on how to avoid making a mistake when you or your purchase department goes on a shopping trip.

Let's get started!

Temperature in a nutshell🥜

Yes, we're starting from scratch!

Temperature tells us how hot or cold something is. It shows the energy of motion at the small molecular level. When something gets hot, molecules move fast. When something gets cold, they move slowly.

You can measure temperature in units such as Celsius, Fahrenheit and Kelvin. In the process industry, Celsius is most commonly used.

How temperature affects a hose⚙️

From extreme temperature fluctuations in one operating environment to aggressive substances with a very high constant temperature in another, there is no hose that is suitable for all situations.

The operating temperature of a process plant directly influences the properties and performance of a hose. Therefore, it is important to choose the right hose for each specific situation.

So how is a hose affected by temperature? Let's take a look at some of the most well-known physical properties:

- Hardness: At high temperatures, the hose often becomes softer, which typically increases its flexibility. However, at lower temperatures, it can become more rigid, which can make it vulnerable to damage, especially when bending or moving.

- Abrasion resistance: Temperature does not affect the abrasion resistance of the hose.

- Chemical resistance: High temperature can change the chemical resistance of the hose, making it more vulnerable to certain chemicals or gases in the system. Low temperatures can have the opposite effect.

- Pressure resistance: Pressure resistance: The ability of the hose to withstand pressure is affected by temperature. For example, a hose operating at high temperature will have its pressure resistance reduced.

But there are, of course, some situations where the above is not entirely true. This is mainly due to the construction of the hose.

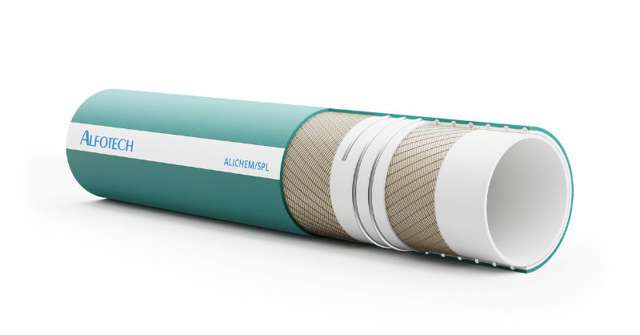

For CIP cleaning, which typically takes place at temperatures between +75°C to +85°C, the hose must be able to handle strong chemicals at high temperature. At Alfotech, we typically suggest chemical hoses from the Alichem series, as the EPDM rubber with polyester reinforcement is ideal for this purpose.

3 vigtige tips til shoppingturen🛒

Understanding the impact of temperature on the hose is crucial to making the right choice when shopping with your supplier. But it's not the only factor.

Here are a few tips for your shopping trip:

- Understand the temperature requirements: You should know the temperature conditions the hose will be operating under. This includes both the surrounding production environment and the media(s) that will pass through the hose.

- Understand pressure requirements: Temperature and pressure are closely related in any process plant. What is the working pressure at the normal operating temperature? Generally, the higher the temperature, the lower the pressure the hose can operate at. Please note that the pressure specifications of a hose are always specified at a temperature of +20°C by the supplier!

- Save money with variants: When shopping, it can be a good idea to buy hoses with different temperature limits. This way you can make sure they fit all your installations and you can save money by buying the ones that suit your needs.

At Alfotech, we stock several categories of industrial hoses and can of course advise you on the best hose solution for your needs. With more than 35 years of experience in the process industry, there is hardly any application scenario we are not familiar with.

What's coming next?📅

In the next edition of the Hose Selection Guide, we take a closer look at the role of pressure, including its relation to working temperature, the importance of pump types and more. We'll also explore how pressure can drop as temperature rises - and the risks this can have on the operational stability of your process plant.

da

da

de

de

en

en

sv

sv