Milk hoses

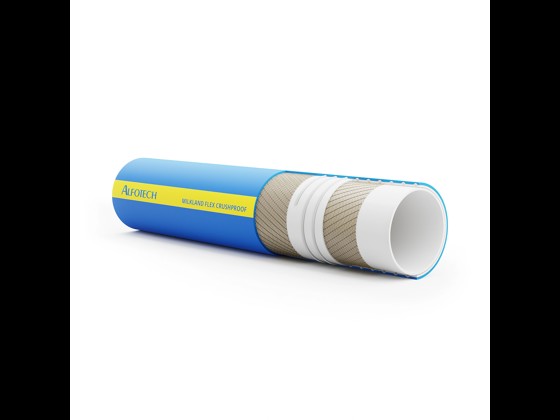

Milkland, Mastermilk, Milkland Flex, Milkland Crushproof...

Beer & beverage hoses

Beverage Plus, Beverage CLC/10, Unifood Flexperform etc.

Oil & fatty food hoses

Oily Food/10, Lightfood/SD, Oily Food/SPL etc.

Pharmaceutical hoses

Dynamic CLC, Dynamic Antistatic, Pharmaflon etc.

Chemical hoses

Alichem, Alichem/SPL, Manipharm-C/SD-UPE etc.

Granules and powder hoses

Air Food Antistatic, Granofood, Silo/SPL etc.

Product & steam hoses

Food Steam, Biovast, Soffione

Silicone hoses

Clearway-D Platinum, Clearway-SD Platinum etc.

Teflon tubes & hoses

FoodForce C, PharmaForce C, ChemForce ATEX etc.

Stainless steel bellows hoses

Bellows hoses in stainless steel (AISI 316)

Thermoplastic hoses

Pharma Press, Pharmasteel Press, Crystal Clear 55

Cleaning & low pressure hoses

Geyser, Food Water, Thermoclean 100 etc.

Composite hoses

Chem SD, Food 500, Oil SD etc.

PVC hoses

Tubclair AL, Tricoclair AL, Tress-Nobel etc.

Polyurethane hoses

Vacuum hoses, food hoses, spiral hoses etc.

Pneumatic hoses

Air hoses & compressed air hoses etc.

Hose guards

Smooth, 2-piece & spiral hose guards etc.

Hose racks

AG hose racks

Stainless hose reels

Hose reels, wall brackets, rewind kits etc.

Custom hoses

El-traced hoses, double-jacket hoses, grounded hoses etc.

Everything you need to know about industrial hoses

We've been working with industrial hoses for more than 35 years - and we're still passionate about it. It started with customized hose solutions for the process industry in Denmark, but today our hoses are an important part of production across Europe in the food, medical and chemical industries.

With years of experience, we’ve gained a deep understanding of what it takes - from specific solutions to complete traceability and documentation. We deliver products that meet the highest standards of safety and efficiency while continuously expanding our range. Our development never stops, so we can always adapt to your needs - both today and in the future.

Whether you produce milk powder, jam or alkene beverages, we have solutions to suit your needs. In this guide, we give you a basic introduction to industrial hoses - where they’re used, their main properties and what parameters you need to consider when choosing a hose for your process plant. We also take a closer look at accessories that are often needed to ensure the most reliable solution.

Read along and learn more!

What are industrial hoses?

Industrial hoses - also known as process hoses - play a central role in the process industry. They make it possible to handle liquids, gases and granulates efficiently and safely. In short, they ensure that the medium is transported from A to B smoothly, while protecting both the environment and the product itself. And let's be honest: no one wants to experience downtime due to poor hose solutions.

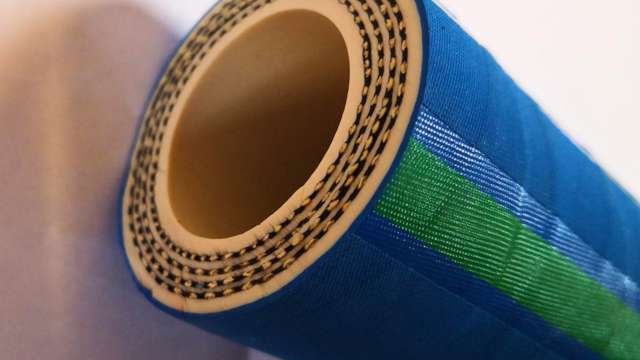

Industrial hoses are often made of materials such as EPDM, nitrile (NBR), PFA or silicone, but you can also find them in Teflon (PTFE) and metal. Each material has its particular strengths, especially when it comes to handling high temperatures and pressures. In many cases, multiple materials are combined to create the optimal solution for your process plant.

Hoses are not just accessories – they’re a key component of your piping system, whatever your production. They ensure that the flow is both stable and optimal, so you can avoid annoying downtime and unexpected challenges. With the right hose solution, you can focus on what matters most - keeping production running smoothly.

Reliable quality solutions for the process industry

Food industry

Food transportation is about more than just logistics - it's about safety and quality. Our food-approved industrial hoses are designed to ensure taste- and odor-free transport of everything from milk and juice to beer, minced meat and spirits. Developed with flexibility, durability and safety in mind, they’re perfect for dairies, breweries and meat processors. With our deep understanding of relevant legal requirements for food contact materials in the food industry and traceability, the vast majority of our models comply with several applicable regulations and legal requirements, including EC 1935/2004 and 2023/2006/EC (GMP), Italian legislation D.M. 21.03.73 and US FDA legislation.

Chemical industry

The chemical industry needs robust hose solutions that can handle aggressive chemicals and harsh production environments. Our range of chemical resistant hoses - such as chemical hoses, thermoplastic hoses and composite hoses - are built for maximum performance even in the toughest production. The materials are carefully selected for their chemical resistance and the built-in reinforcement protects against wear and damage. Several of the hoses are anti-static and ATEX-approved, so they can also be used in hazardous areas. Looking for a versatile hose solution for your chemical production? Then take a look at our Manipharm-C/SD-UPE hose with built-in steel spiral - perfect for transporting harsh chemicals.

Pharmaceutical industry

In the pharmaceutical industry, compromises are rarely made when purchasing industrial hoses, because hygiene and precision are crucial. That's why our pharmaceutical hoses are designed to meet the strictest of manufacturers' requirements. The hoses ensure sterile transportation and are often made from materials such as silicone and Teflon that are resistant to chemicals, high temperature and pressure. The hoses come with batch numbers, documentation and full traceability. And what about the standards, you might ask? Don't worry - most of our models comply with USP Class VI, ISO10993, REACH, RoHS and more. With our pharmaceutical hoses, you not only get a high-quality solution, but you also get a guarantee of precision and reliability down to the smallest detail.

Safe and efficient powder transport with granule hoses

Transporting powders and granules requires industrial hoses that can handle everything from abrasive materials to high temperatures and pressure. Our granulate hoses are designed to meet most challenges, whether you work with milk powder or other types of granules. They’re built to withstand abrasion from even the most demanding materials while delivering reliable performance.

Static electricity is sometimes an overlooked risk in production environments, but it can have serious consequences. That's why all our granulate hoses come with antistatic properties that minimize the risk of sparks and build-up of static electricity. This makes them particularly suitable for work areas where safety is paramount.

Not sure which granular hose will best suit your application? Our news article on hoses for powder transportation not only gives you an insight into where and when granular hoses are used, but also highlights their general benefits. In addition, we also take a closer look at models from our other hose categories.

Uncompromising cleaning solutions

In the process industry, frequent and thorough cleaning is essential to ensure optimal hygiene and efficient production. This is where cleaning methods like CIP (Clean-In-Place) and SIP (Sterilization-In-Place) come in as indispensable tools to maintain high standards. But did you know that success with these methods depends on the right equipment?

CIP and SIP place high demands on industrial hoses and cleaning equipment as they typically involve extreme conditions such as high temperatures, high pressure and aggressive chemicals – for example alkaline detergents or lye. Here we often recommend our food-approved Alichem/SPL and Alichem CLC/10 hoses. Their robust construction makes them perfect for these challenging applications.

For everyday cleaning tasks, such as foam application, our low pressure and cleaning hoses are the ideal choice. They combine flexibility and robustness with impressive resistance to both chemical cleaners and disinfectants. Whether you choose Foam Cleaner, ISAR Water or Thermoclean 100 Antimicrobial, you get a long-lasting, high-performance solution. This means you can focus on effective cleaning without worrying about hoses that aren't up to the task.

Comparison: Our best cleaning hoses

We set out to compare the best cleaning hoses on our shelves; Foam Cleaner, ISAR Water and Thermoclean 100 Antimicrobial. Vastly different in their specifications but all designed to keep the process plant clean - and preferably in combination with other relevant cleaning equipment such as flush guns, nozzles/lances and stainless hose reels.

Frequently asked questions

What factors should you consider when choosing the right industrial hose?

When choosing the right industrial hose for your needs, there are several factors to consider. First, you should ensure that the hose is suitable for the intended use. In addition, it’s important to determine if it can handle the temperatures and pressures of the process plant. Other factors such as chemical resistance, antistatic properties, certifications and approvals can also be important to consider.

What are the most common types of accessories for industrial hoses?

There are many different types of accessories for industrial hoses. The most common include hose couplings, BSP fittings, hose clamps, hose guards and hose reels.

What are the benefits of choosing high-quality industrial hoses and accessories?

High-quality industrial hoses and accessories reduce the risk of production downtime, optimize work processes and lower long-term costs by minimizing wear and failure. In many cases, you also improve both hygiene and safety.

What does traceability mean in industrial hoses and accessories?

Traceability refers to the ability to follow an industrial hose or associated product through the entire supply chain. It includes information about origin, manufacturing process, materials used, test procedures and inspections. Traceability ensures quality and documentation, which is important in many forms of production within the process industry.

Which hose couplings fit your industrial hoses?

Our industrial hoses are compatible with a wide range of hose couplings designed for different needs and applications. Our product categories include crimped hose couplings, reusable hose couplings, stainless hose clamps, Camlock-couplings, TW couplings and more.

da

da

de

de

en

en

sv

sv