Synthetic rubber plays a crucial role in the process industry and is used in everything from conveyor belts and gaskets to sealing materials and rubber hoses. As a versatile material, it’s known for its impressive resistance to many different substances and its robustness under demanding production conditions.

Two of the most common types of rubber often used in the construction of the inside of industrial hoses are EPDM (Ethylene Propylene Diene Monomer) and NBR (Nitrile Butadiene Rubber), the latter also known as nitrile rubber. But what makes them different and how do they differ in performance when it comes to the rubber hose and its ability to transport different types of media?

In this miniguide, we focus on both types of rubber and give you a full overview of their properties, benefits and limitations. And we'll help you understand why you should consider them the next time you go shopping. Last but not least, we reveal our best-selling rubber hoses of 2024.

Learn more in just 5 minutes!

What is synthetic rubber?

Synthetic rubber is an artificially produced material that mimics the properties of natural rubber. Unlike natural rubber, which is extracted from latex tapped from rubber trees, synthetic rubber is produced by polymerization (a chemical process that binds small molecules together into long chains) of monomers (small chemical building blocks that can be assembled into larger structures) such as styrene, butadiene and isoprene. The process creates long molecular chains that give the material its characteristic flexibility and durability. The type of rubber and its properties depend on the selected monomers and additives, which can be customized to specific needs.

Synthetic rubber is often manufactured in large chemical plants and production facilities that have easy access to the necessary raw materials. The largest manufacturers are mainly located in countries such as the USA, China, Germany, South Korea and Japan.

Synthetic rubber is widely used in the process industry, for example in sealing components, rubber hoses and membranes that must withstand extreme environments and demanding production conditions. In food processing, for example, it meets high hygiene and durability requirements, while in chemical and pharmaceutical production it provides reliable protection against strong chemicals, high pressure and extreme temperatures.

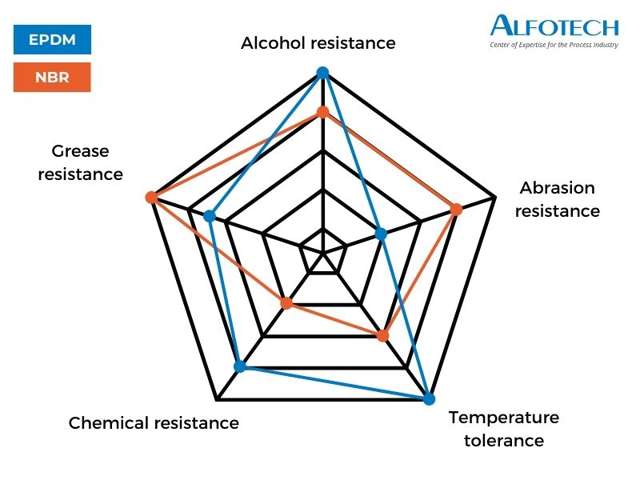

Comparison: EPDM vs. NBR rubber

Features and benefits of EPDM rubber

In general, EPDM rubber is characterized by being particularly resistant to alcohol, high temperature and chemicals. Therefore, it’s also widely used in industrial hoses used in the food and chemical industries, for example for transporting acids and bases or for CIP cleaning. As a starting point, EPDM covers a temperature range of approximately -40°C to +150°C, but in practice its performance depends on what is going through the rubber hose. For example, certain chemicals affect the durability of EPDM rubber more than others. This type of rubber is less resistant to grease and is therefore not normally used in rubber hoses for the transportation of oil or fatty media.

Features and benefits of NBR rubber

NBR rubber is the preferred choice for rubber hoses intended for the transportation of powdery, oily or fatty media. In addition to its high fat resistance, it’s also characterized by its high abrasion resistance, which is why this type of rubber is used in some granulate hoses. For high friction, for example when transporting milk powder or other types of solids, NBR is significantly better than EPDM. Although NBR can't match EPDM in temperature tolerance, it works optimally at moderate temperatures from -30°C to +100°C (briefly up to +120°C). As with EPDM, it depends on several factors such as pressure and material composition.

How do you make the best choice?

The choice between an EPDM or NBR-lined rubber hose depends on your specific production requirements, especially the media to be transported, pressure and temperature requirements and the environmental conditions where the rubber hose will be used.

Perhaps you work with hot liquids, vapor or chemicals such as acids and alcohol? If so, a rubber hose with an EPDM-liner is the obvious choice because its construction makes it more resistant to temperatures and chemicals. However, if the task at hand involves the transportation of cooking oil or flour, i.e. media that is either fatty or has high friction, then an NBR-lined rubber hose is the way to go. In terms of alcohol resistance, EPDM is marginally better than NBR, but you can actually use both in most cases.

Our 3 most popular rubber hoses in 2024

Sales figures never lie - including those for 2024. We put them under the microscope to find last year's most popular rubber hoses with either EPDM or NBR inner liners. Here are three of our most requested models, all meeting the highest standards in the process industry:

Oily Food/SPL

As the name suggests, our food-grade rubber hose Oily Food/SPL is tailor-made for the transportation of oil and faty media in food production. In addition to being constructed with an NBR inside, the model is also equipped with a steel spiral, which makes it extra flexible. Oily Food/SPL covers a temperature range from -20°C to +90°C and can be briefly sterilized at +130°C. Covers working pressures up to 10 bar. Also available in a crushproof version that withstands collisions.

Food Steam

Our FDA-approved Food Steam hose is designed with a smooth EPDM rubber surface both inside and out. The construction makes it not only ozone and weather resistant, but also very robust. Food Steam is especially suitable for cleaning with hot water or steam, but can also be used to transport non-fatty foods. The rubber hose can handle temperatures from -40°C up to +164°C. Maximum working pressure of 20 bar at +95°C for hot water and 6 bar at +164°C for steam.

Alichem/SPL

Our robust and flexible Alichem/SPL chemical hose has been in the spotlight before, for example in our late summer guide to CIP cleaning. With an EPDM inside and built-in steel spiral, it is suitable for light chemical liquids and non-fatty foods. In CIP processes, for example, it can easily handle concentrations of mixed liquids, but not highly concentrated acids. Alichem/SPL works optimally at temperatures from -40°C to +120°C depending on the medium and can be sterilized at +140°C for max. 30 minutes.

Need advice and guidance?

Still not sure when you should choose a rubber hose with an EPDM liner over one with NBR for your needs? We know it can be a difficult choice to make. But don't worry - our sales consultants are always ready with advice and valuable guidance when you need it. They can help you find the right rubber hose for your production requirements.

Contact them today via email inquiry@alfotech.eu or give them a call on +45 7020 0422.

da

da

de

de

en

en

sv

sv