Mechanical seals for APV products

CXC, ZMS, SRG, W, WS+, SIM etc.

Mechanical seals for Alfa-Laval products

ALC, FM, GM, LKH Contherm etc.

Mechanical seals for Fristam products

Mechanical seals with high seat, low seat etc.

Mechanical seals for SSP products

SSP SR, IBEX, IBEX MOG

Mechanical seals for Johnson products

OL, Top Wing, Acculobe etc.

Mechanical seals for Inoxpa products

SLR, Prolac, EFI

Mechanical seals for Jabsco products

Jabsco Hyline

Mechanical seals for Tuchenhagen products

TNHG

Mechanical seals for Hilge products

Novalobe, HG

Mechanical seals type MG

MG 1, MG 12, MG 13

Mechanical seals for agitators

HCL

Mechanical seals - others

Type 212, BT, 130, 152 HQR etc.

Mechanical seals for the process industry

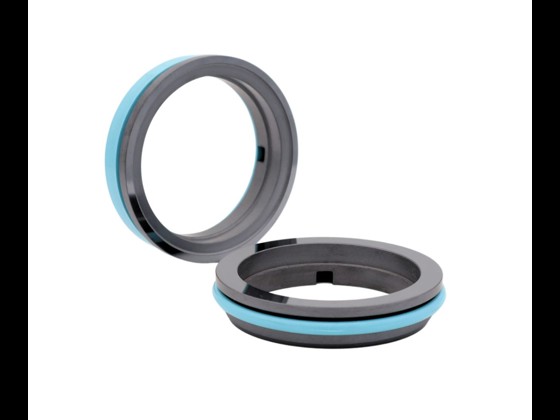

A mechanical seal (also known as a stuffing box) ensures that liquids and gases remain within the desired limits in rotating equipment such as pumps. It forms a tight barrier between the rotating shaft and the pump housing and prevents the medium from leaking into the environment. In hygienic applications, the seal protects both the end product and the system modules from contamination. Mechanical seals are an essential part of many industrial plants and are used in pumps, compressors, turbines and agitators, among other things. They protect the product, ensure stable operation and reduce the risk of downtime and contamination. It is therefore important to choose a sealing solution that matches both the technical requirements and the process environment. We offer a wide range of mechanical seals that are suitable for equipment from a wide range of recognised manufacturers in the process industry.

Sealing solutions for the industry's most widely used equipment types

We offer a wide range of solutions for different needs. Among our most popular models are mechanical seals for Alfa Laval FM pumps and LKH centrifugal pumps, both designed to meet the requirements for ease of cleaning and high sealing performance.

Our range covers seals for equipment from many leading manufacturers in the process industry. In addition to solutions for Alfa Laval, we also offer popular models such as the W+ and WS+ mechanical seals and the SRG mechanical seal for APV pumps – sealing solutions known for their durability and functionality in demanding conditions.

For Johnson pumps, we offer two of the most commonly used types of mechanical seals – including a variant for the TopWing series, designed with a focus on high hygiene standards and CIP/SIP processes, and a seal compatible with the Johnson OL series. Both solutions have been developed with a view to safe operation and long service life in systems with sensitive media.

Inoxpa is also part of the range, which includes SLR and Prolac mechanical seals. Both models have been developed with a focus on hygiene and easy maintenance and are often used in CIP/SIP processes in the sanitary industry.

In addition, we offer seals that fit equipment from a number of other manufacturers in the food, dairy and pharmaceutical industries. Most seals are food-approved and designed to withstand repeated cleaning and high loads. For some manufacturers, we can also supply complete service kits consisting of the necessary o-rings, so you can easily maintain and extend the service life of your equipment.

What to consider when selecting a mechanical seal

The right choice of mechanical seal depends on several parameters, including the nature of the medium, temperature and pressure conditions, and whether CIP, SIP or manual cleaning methods are used. In hygienic environments, both the seal and associated gaskets must be able to withstand cleaning agents and high temperatures without compromising sealing performance.

In addition, safety requirements, emission levels and the risk of cross-contamination should be taken into account, especially in pharmaceutical production and the food industry.

Find the right mechanical seal for your process and equipment

Mechanical seals are designed to ensure leak-free operation in rotating equipment and are often critical components in both food and pharmaceutical production. This requires a seal that can withstand pressure and temperature while meeting hygienic standards.

When choosing the right mechanical seal, it is important to consider several parameters, including seal type, media, temperature, CIP/SIP compatibility and, not least, shaft diameter. The latter is crucial to ensure that the seal fits correctly and functions optimally in the specific equipment.

Want to know more about how a mechanical shaft seal works and why the material is so important?

In this video, we go through the basic principles: from the difference between rotating and stationary surfaces to the importance of fluids and the choice of materials such as carbon, ceramics and silicon carbide.

Maximum flexibility and reliability through compatible material selection

The design and materials of seals play a key role in both durability and process compatibility.

The construction and materials of the seals play a key role in both durability and process compatibility. We offer seals in combinations such as carbon against stainless steel, carbon against ceramics, and silicon carbide and tungsten carbide in various variants. For rubber components, NBR, EPDM, FPM and PTFE are used depending on the temperature, chemical and cleaning requirements.

The high degree of compatibility and variety in material selection means that we can deliver a solution that fits your operating conditions precisely – whether you are working with aggressive media, high pressures or sterile environments.

Frequently asked questions

What is a mechanical shaft seal?

A seal that prevents leakage between a rotating shaft and the surrounding housing – typically in pumps, mixers or other rotating equipment

What is the purpose of a mechanical seal in hygienic applications?

In applications with high hygiene requirements, the mechanical seal protects both the end product and the equipment from contamination and the ingress of foreign matter.

Which manufacturers are supported with your seals?

We offer compatible solutions for equipment from Alfa Laval, APV, Johnson and several other manufacturers in the process industry.

Are the seals food-approved?

Yes, the vast majority of mechanical seals in our range are made from materials approved for contact with food and comply with applicable standards.

Can I use the same mechanical seal for both hot and cold media?

That depends on the choice of materials and process conditions. We offer seals that can withstand both high and low temperatures – contact us for advice.

da

da

de

de

en

en

sv

sv