Teflon tube, PTFE, smooth

Smooth PTFE, available in various colors

FEP tube, clear, smooth

FDA approved, transparent, non-flammable

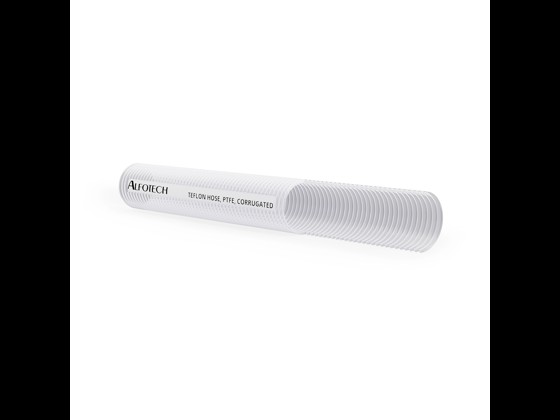

Teflon hose, PTFE, corrugated

FDA approved, natural color, -70°C to +260°C

FoodForce C

Corrugated PTFE, stainless steel braid, -73°C to +260°C

FoodForce S

Smooth PTFE, stainless steel braid, -73°C to +260°C

PharmaForce C

Corrugated PTFE, stainless steel braid, silicone

ChemForce ATEX

Corrugated PTFE, ATEX-approved, stainless steel braid

Teflon coiled tube

FDA approved, smooth, made to order

Teflon hoses – High-quality PTFE solutions

We offer flexible, high-quality teflon hoses, also known as PTFE hoses, which can be used in many types of process plants. Our range includes both smooth and PTFE corrugated hoses, which are suitable for transporting food, pharmaceutical products, chemicals and other media under demanding conditions. All our hoses are made from 100% Virgin PTFE, which means that the material is completely pure without any recycled material or additives. This ensures maximum durability, chemical resistance and optimal performance in industrial processes.

Our teflon hoses are used in many industries. In the food industry, food and beverages are transported under hygienic conditions where cleanliness and food approval are crucial. In the pharmaceutical industry, active ingredients and medical products are handled, where traceability and cleanliness are paramount. The chemical industry uses teflon hoses to transport aggressive chemicals, where safety and material stability are essential. The oil and gas industry also uses our hoses to handle products under high pressure and temperature.

Advantages of teflon hoses

Teflon hoses are known for their wide temperature resistance and chemical resistance. They can be used at temperatures ranging from -70°C to +260°C and can withstand the transport of aggressive media without risk of deformation or deterioration. PTFE's non-stick properties ensure optimal flow, reducing the risk of clogging and making cleaning easier. This is particularly important in food and pharmaceutical applications, where hygiene and cleanliness are paramount.

Our stock range also includes models that are well suited to production environments with very high demands on temperature, pressure and/or chemical exposure – for example, with aggressive liquids. These PTFE corrugated hoses, including FoodForce C, are constructed of corrugated PTFE on the inside and protected on the outside by a PTFE hose with stainless steel braid, making them highly resistant to both temperature and pressure without losing their mechanical properties.

If there are very high hygiene liners, such as in laboratory environments in connection with pharmaceutical production, it is worth looking at our PharmaForce C model. PharmaForce C is coated with a transparent silicone cover, which gives the hose a smooth outer surface that is easy to clean after use.

All our Teflon hoses, both with and without stainless steel braid, are available in sizes from 1/4‘ to 10’ (DN8 to DN250).

All hoses are food-approved and can be sterilised, ensuring safe handling of food and medical products.

Have you read our tubing mini-guide?

In the mini-guide, we provide you with a detailed overview of the materials FEP, PTFE and silicone, including their unique properties and what makes them ideal for different applications and production needs. We focus on flexibility, temperature resistance and chemical resistance.

Be better equipped to make the right choice.

Documentation and calibration

Quality and documentation are a central part of our offering. Each PTFE corrugated hose comes with documentation, including material certificates and pressure test reports, ensuring full traceability and compliance with applicable standards. The hoses can be integrated with calibration equipment, such as laser gauges, which measure pressure and flow accurately. This enables our customers to maintain high liners of process control and safety in their facilities.

Easy installation with push-in fittings

We make the installation of teflon hoses simple and safe with push-in fittings that ensure tight connections without the use of special tools. This makes it quick to integrate the hoses into existing systems, while ensuring that they are correctly positioned during operation. We also offer tailor-made solutions where hose lengths, diameters and fittings are adapted to the customer's needs. This optimises processes and ensures maximum efficiency and safety in all applications.

Frequently asked questions

What types of teflon hoses do you offer?

We offer both smooth and PTFE corrugated hoses in various diameters and lengths, adapted to everything from food production to chemical processes.

What material is used in teflon hoses?

All our hoses are made from 100% virgin PTFE, ensuring high-quality, chemical resistance and long service life.

How is the quality of the teflon hoses ensured?

We supply all hoses with comprehensive documentation, including material certificates and pressure test reports, which ensure traceability and compliance with applicable standards.

Can teflon hoses be sterilised?

Yes, all our teflon hoses are food-approved and can be sterilised, making them safe for use in food and pharmaceutical applications.

How are Teflon hoses installed?

Our hoses can be installed with push-in fittings, which ensure a quick and tight connection without the use of tools, while ensuring that the hose is correctly positioned during operation.

da

da

de

de

en

en

sv

sv