Camlock coupling sleeve, type A

Stainless steel, female/internal BSPP thread

Camlock female coupling, type B

Stainless steel, external BSPP thread

Camlock female coupling, type C

Stainless steel

Camlock female coupling, type D

Stainless steel, internal BSPP thread

Camlock coupling, type E, hose tail

Stainless steel, for clamp jaws

Camlock coupling, type F

Stainless steel, external BSPT thread

Camlock dust cover, type DC

Stainless steel

Camlock dust plug, type DP

Stainless steel

Camlock coupling sleeve, type A, polypropylene

Female/internal BSPP thread, good for chemistry

Camlock female coupling, type B, polypropylene

Incl. stainless steel cam arms & pins, good for chemistry

Camlock female coupling, type C, polypropylene

Incl. stainless steel cam arms & pins, good for chemistry

Camlock female coupling, type D, polypropylene

Internal BSPP thread, good for chemistry

Camlock hose tail, type E, polypropylene

Good for chemistry

Camlock dust cover, type DC, polypropylene

Good for chemistry

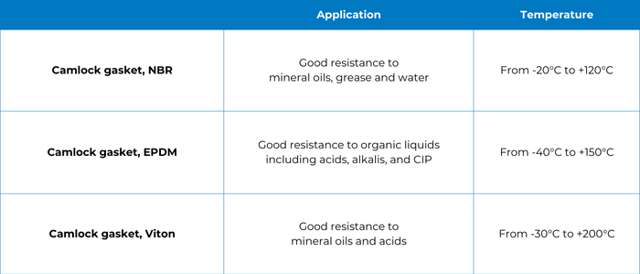

Camlock gasket, NBR

Oil resistant, not suitable for CIP

Camlock gasket, EPDM

Good resistance - not suitable for mineral oils and greases

Camlock gasket, Viton

Good resistance - not suitable for steam and lye

Camlock gasket, PTFE/EPDM

Good resistance - Not suitable for CIP

Camlock gasket, NBR, FDA

Good resistance - Not suitable for CIP

Camlock gasket, EPDM, FDA

Good resistance - not suitable for mineral oils and greases

Camlock gasket, Viton, FDA

Good resistance - not suitable for steam and lye

Everything you need to know about Camlock couplings

Camlock couplings are one of the most efficient and reliable hose coupling solutions in the process industry. Their simple and robust design ensures fast and secure connection between hoses, pipes and equipment.

The simple and robust design of Camlock couplings allows for quick and tool-free connection, ensuring efficiency and reducing production downtime. This makes them particularly suitable in industries where equipment regularly needs to be dismantled for cleaning or maintenance. However, it is important to choose the right type of Camlock coupling to suit your specific application. We guide you in choosing the most optimal Camlock solution.

What are Camlock couplings?

Camlock couplings are a practical hose coupling system used in the process industry to quickly and safely connect hoses and pipes. They consist of two main parts: a female coupling with locking arms and a male coupling. When the locking arms of the female coupling are secured around the male coupling, a tight and secure connection is ensured. This design makes Camlock couplings both easy to use and highly reliable.

Construction: Camlock couplings are made from robust materials such as stainless steel AISI 316, making them corrosion resistant and ensuring long durability. We carry a wide range of quality couplings in different materials.

Applications: These couplings are indispensable in industries where safe and quick connection is essential, such as food production, chemical handling and petrochemical industries. Their ability to withstand high pressure and extreme temperatures makes them suitable for transporting liquids, powders and gases. Stainless steel Camlock couplings are ideal for the food industry as they ensure hygienic transportation of both liquid and solid products.

Camlock coupling types: Differences between type A, B, C, D, E and F

Camlock couplings come in several variants, each designed for specific needs. These include both male and female couplings:

- Camlock Type A (male coupling with internal thread): This type is equipped with a male coupling with internal thread, ideal for connecting pipes and fittings. It is often used in processes where a secure and tight connection is essential. The internal thread makes it easy to connect to pipe systems of different sizes.

- Camlock Type B (female coupling with external thread): Type B has a female coupling with external thread, making it compatible with a wide range of fittings and pipes. It is popular in the process industry for its flexible applications and easy installation. The locking arms ensure a reliable connection that prevents leaks.

- Camlock Type C (female coupling with hose connector): This variant combines a female coupling with a hose connector, allowing easy connection of hoses via hose straps or clamps (stainless steel or aluminum). It is ideal for transporting liquids and gases in various industries and ensures a tight connection between hoses and equipment.

- Camlock Type D (female coupling with internal thread): Type D has a female coupling with internal thread for direct connection to pipes and fittings with external thread. It is used in applications where a tight connection is needed to prevent leakage. It is also easy to maintain and replace.

- Camlock Type E (male coupling with hose connector): Type E combines a male coupling with a hose connector and is perfect for quick and efficient hose connection with hose straps or clamps. It ensures a tight and secure connection, preventing accidental leakage.

- Camlock Type F (male coupling with external thread): Designed with a male coupling with external thread, the Type F is used to create a secure connection with pipes or fittings with internal threads. It is suitable for applications that require a robust and durable connection and is easy to integrate into different pipe systems.

Each type has its own specific application and it's important to choose the right one to ensure the best and most secure connection.

Benefits and applications of Camlock

One of the biggest benefits of Camlock couplings is their ability to optimize work processes. By being able to be assembled and disassembled without tools, the time needed for maintenance and equipment changeover is significantly reduced. Thanks to their versatility and durability, Camlock couplings are widely used in the food, chemical and pharmaceutical industries.

Accessories for Camlock couplings: Gaskets

Accessories play an important role in ensuring an optimal and tight connection. A Camlock gasket is indispensable and ensures the coupling is tight and prevents leakage. A specific product that meets these needs is the Camlock gasket NBR, which is available in different materials depending on the fluids or substances to be transported. Choosing the right gasket will extend the life of the coupling and ensure safe operation.

Flexible adapter solution

Whether you work with fixed installations or use IBC pallet tanks in production, this Camlock adapter with matching union nut is an easy and flexible solution that can help you save a lot of time in your daily operations. The Camlock adapter not only comes in food grade quality, but also supports DS, SMS and SAV standards.

How we can help you

We have a wide range of Camlock couplings and accessories to suit your industrial needs. Our experts are ready to advise you on choosing the right coupling and accessories for your application. We offer high-quality products and ensure you get a solution that is both durable and reliable.

Contact us now by phone +45 7020 0422 or via inquiry@alfotech.eu for professional advice.

Frequently asked questions

How do you install a Camlock coupling?

Installing a Camlock coupling is easy and requires no tools. First, insert the male coupling into the female coupling and lower the locking arms on the female coupling to ensure a tight connection.

What are the differences between NBR, EPDM and Viton Camlock flat gaskets?

Camlock gaskets are available in different materials including NBR, EPDM and Viton rubber, each with their unique properties. NBR rubber is known for its oil resistance, EPDM is ideal for water-based liquids, while Viton rubber is resistant to aggressive chemicals.

da

da

de

de

en

en

sv

sv